LYXCTECH Laser Welding Machine

-

Laser welding VS Traditional welding

Laser welding is a process that offers maximum control over the heat input, allowing just the right amount of heat to be applied to precise locations.

High-efficiency welding processes

Lower heat affected zone (HAZ)

Less heat distortion & part deformation

Ideal for thin materials & small components

Can join dissimilar metals without filler material

Repeatable results

Minimal machine wear & tear -

Water-Cooled VS Air-Cooled

Water-cooled welding machine: complicated structure, bigger volume, suitable for large-scale factories...

Air-cooled welding machine: simpler structure, smaller volume, lower costs, suitable for light welding, DIY, small workshop...

The cooling capacity of air-cooled welding is weaker than water-cooled welding. However, water cooling systems have high maintenance costs and require regular water replacement and cooling system cleaning. -

Various welding

In addition to basic welding machines, we also provide platform-type, fully enclosed laser welding machines that can achieve batch welding of precision parts.

A variety of welding methods:butt welding, lap welding, stitch welding, fillet welding...

Suitable for a variety of materials: Carbon steel, aluminum plate, stainless steel, copper, brass...

Depending on the material and thickness, the welding parameters are also different. Please consult us for details.

-

LYXCTECH 300W Portable Laser Spot Welder 6J Laser Spot Welding Machine

Regular price $3,599.00 USDRegular priceUnit price / per -

LYXCTECH Air-cooled Laser Welding Machine 1200W Laser Welder Machine 220V ALW-1200A

Regular price $4,999.00 USDRegular priceUnit price / per -

LYXCTECH 1400W Laser Welding Machine Air-cooled With Auto Wire Feeder

Regular price $7,399.00 USDRegular priceUnit price / per -

US STOCK 2-in-1 Laser Welding Machine for Welding and Weld Seam Cleaning 1500W/2000W/3000W

Regular price From $6,699.00 USDRegular priceUnit price / per -

LYXCTECH Mold Laser Welding Machine 200W/400W For Various Mold Repair Welding

Regular price From $7,699.00 USDRegular priceUnit price / per -

LYXCTECH Platform Automatic Laser Welding Machine 1000W 1500W 2000W 3000W Laser Welding Machine MAX 220V

Regular price From $18,999.00 USDRegular priceUnit price / per -

LYXCTECH Fully Enclosed Platform Automatic Laser Welding Machine 1500W/2000W/3000W With 1300*970mm Working Area

Regular price From $22,099.00 USDRegular priceUnit price / per -

LYXCTECH Portable Laser Welding Cart for ALW-1200W Air-cooled Laser Welding Machine

Regular price $659.00 USDRegular priceUnit price / per -

LYXCTECH Welding Nozzles Laser Nozzle for Welding Gun Laser Welding Machine

Regular price From $39.00 USDRegular priceUnit price / per -

LYXCTECH Welding Nozzles Laser Nozzle for Air-cooled Laser Welding Machine Welding Gun

Regular price $169.00 USDRegular priceUnit price / per -

LYXCTECH Fiber Laser Protective Lens for Handheld Laser Welding Machine 1000/1500/2000W

Regular price $41.90 USDRegular priceUnit price / per -

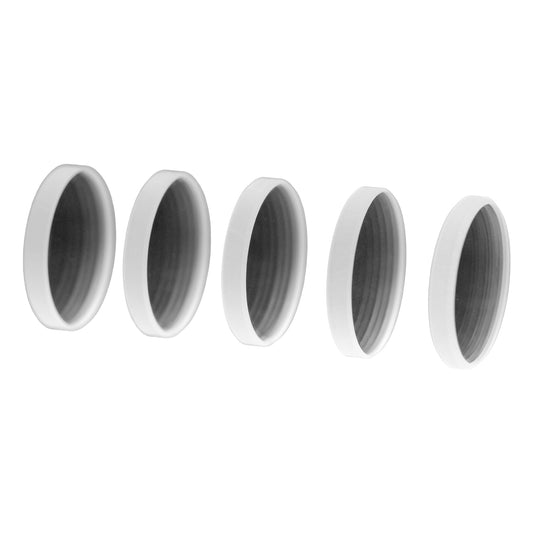

LYXCTECH 5PCS Laser Protective Lens for Air-cooled Laser Welding Machine 1200W

Regular price $39.00 USDRegular priceUnit price / per