Luoyang SFX Industrial Technology Co.,Ltd

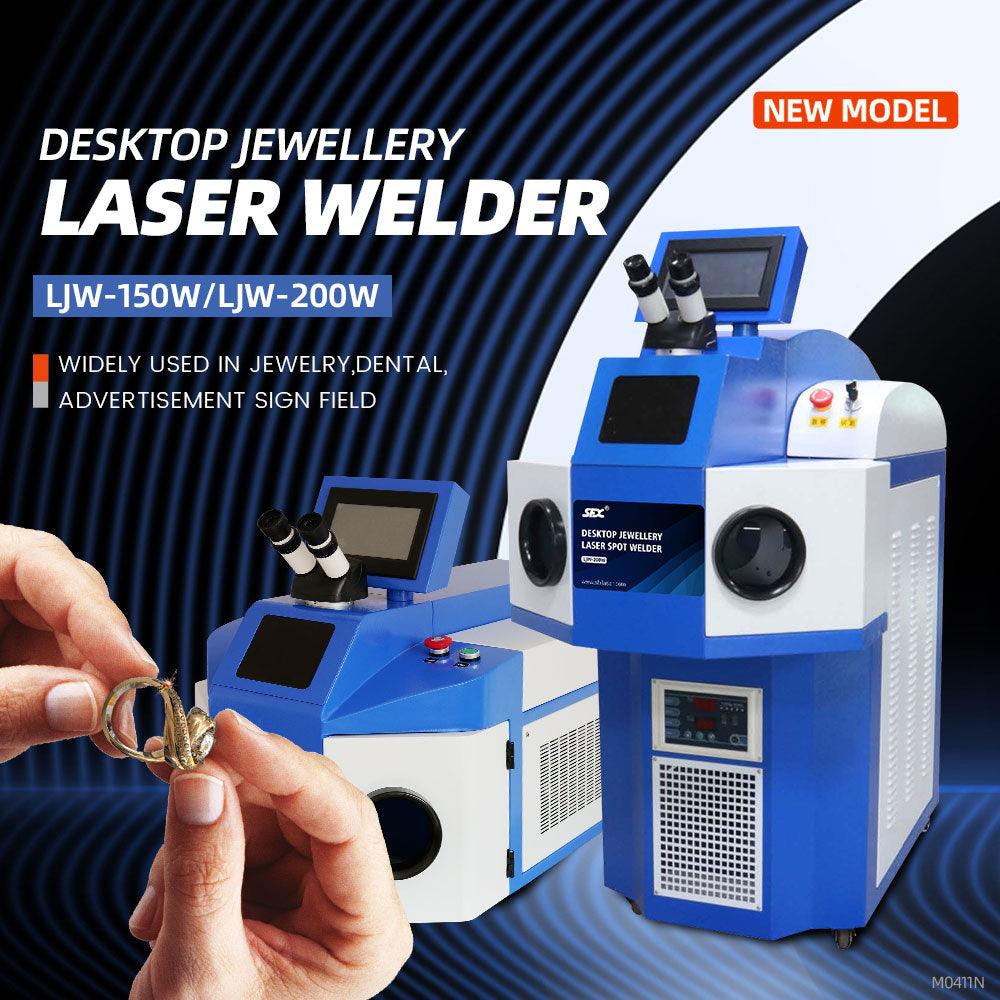

LYXCTECH 150W Jewelry Laser Welder Machine Jewelry Spot Welder 40J Laser Jewelry Welder Machine LJW-150

LYXCTECH 150W Jewelry Laser Welder Machine Jewelry Spot Welder 40J Laser Jewelry Welder Machine LJW-150

Couldn't load pickup availability

About this item

About this item

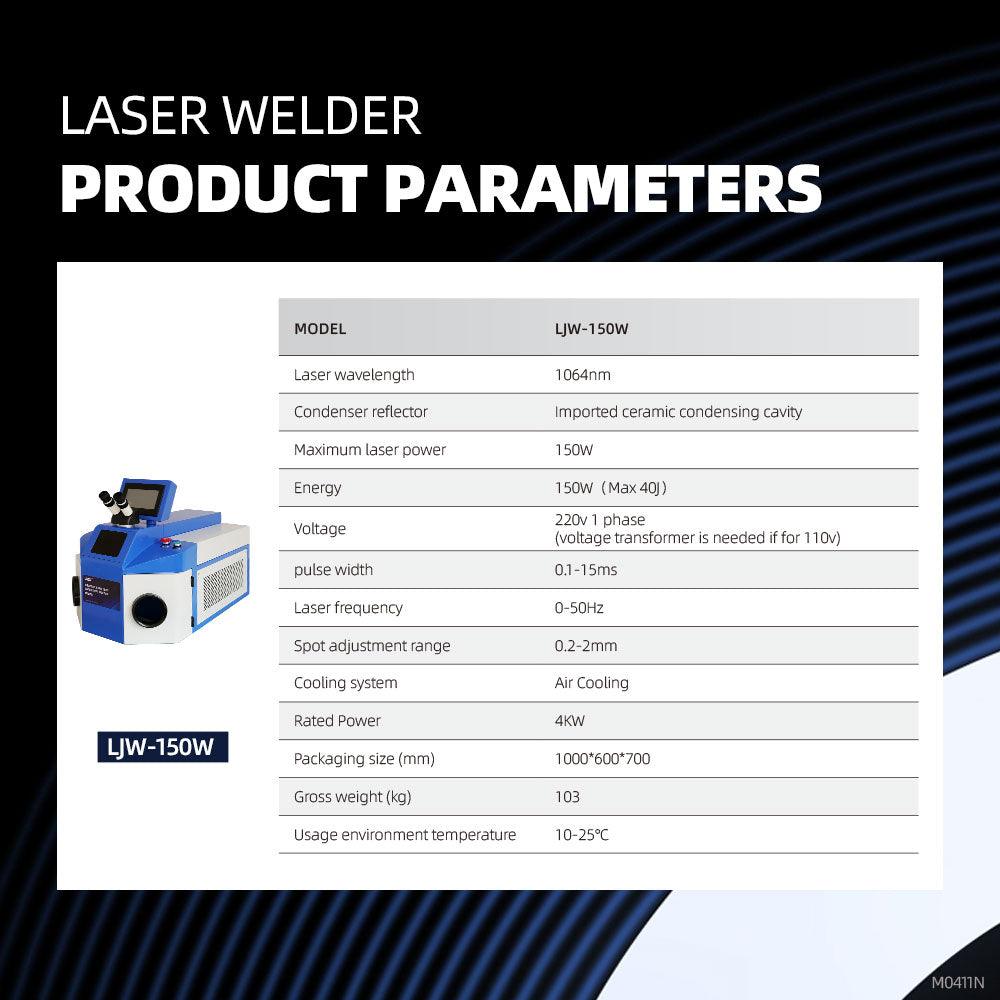

🚀Laser Power: 150W; Laser wavelength: 1064nm; Voltage: 220V 1 Phase; Pulse width: 0.1-15ms; Laser frequency: 0-50Hz; Spot adjuatment range: 0.2-2mm; Cooling system: Air cooling; Rated power: 4KW.

🚀Microscope--Special microscope observation system equipped with crosshairs. With high-speed electronic filter device to protect the operator's glasses.

🚀Control System--Digital control system is adopted, capacitive touch screen, more sensitive and user-friendly parameter interface than traditional screen, visual display, simple and convenient operation.

🚀Cooling Port--Effectively prevent the machine from overheating due to long service time; Blowpipe--Continuous and stable output to prevent oxidation and blackening of products during welding. Flexible and omni-directional adjustment of blowpipe.

🚀 Application Industrial: For mobile communications industry, the arts and crafts and jewels,and electronic components, sensor appearance, precision machinery, hardware, spare parts for car, etc.

Email: lyxctech@gmail.com

oscar@sfxlaser.com

Whatsapp: +86 13592083781

You can also leave us your comment for your interested items. We will respond within 24 hours! Thanks!

LYXCTECH150W Jewelry Laser Welder Machine Jewelry Spot Welder 40J Laser Jewelry Welder Machine LJW-150

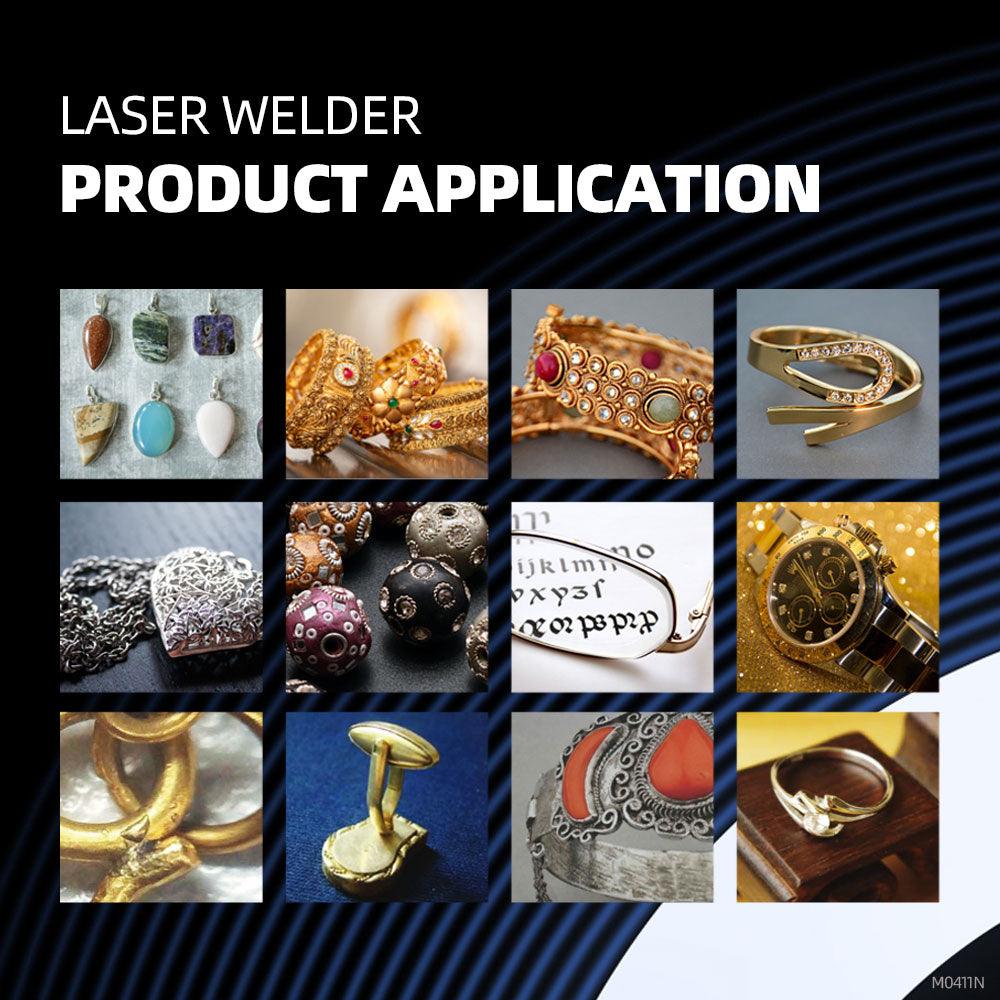

for gold and silver jewelry, rings, pendants, bracelets, necklaces, holes etc.

◐Product Description:

- Jewelry laser spot welding machine is a laser equipment professionally used for welding in the metal jewelry industry. It is mainly used for filling holes, spot welding and repairing gold, silver, stainless steel, titanium alloy and other alloy jewelry. It has the advantages of high precision, low loss, fast speed and so on.

- User-friendly design, ergonomic, long-term work is not fatigue.

- The jewellery welding spot is flat and beautiful, and there is no need for excessive post-weld treatment.

- Fast welding speed, high quality, non-polluting solder joints, precise positioning, no injuring of surrounding jewels during welding.

◒Application industrial:

- For mobile communications industry, the arts and crafts a nd jewels, and electronic components, sensor appearance, precision machinery, hardware, spare parts for car, etc.

◓Application materials:

- Gold, silver, platinum, stainless steel, titanium, and other metals and their alloys. Widely used in gold and silver jewelry, rings, pendants, bracelets, necklaces, holes, spot welding brazing, repair seams and the welding of claw parts of the mosaic parts, etc.

◕Shipping Policy:

- All of our laser machines would be shipped by express like DHL/UPS/FedEx/TNT.

- All prices are including shipping to your door.

- Order processing time: 2 to 3 business days.

- Delivery time: 7 to 15 days.

◉Warranty Policy:

- 1. The warranty period of this product is two years.

- 1.1 From the date of purchasing this product, our company provides free warranty within two years. If the machine need to be returned to the factory for repair, the user only needs to bear the cost of two-way transportation.

- 1.2 This product is repaired free of charge for life, and the user only needs to bear the cost of spare parts and two-way transportation.

- 2. The following scopes are not covered by warranty:

- 2.1 Damage caused by improper use such as violent bumping, bending, etc.

- 2.2 Human-caused damage

- 2.3 Laser accessories and consumables are not guaranteed (galvanometers, field mirrors and other optical parts, Integrated cables, etc. are not covered by the warranty).