Luoyang SFX Industrial Technology Co.,Ltd

LYXCTECH Pulsed Laser Cleaning Machine Desktop Design Laser Machine for Cleaning and Welding 200W/300W

LYXCTECH Pulsed Laser Cleaning Machine Desktop Design Laser Machine for Cleaning and Welding 200W/300W

Couldn't load pickup availability

About this item

About this item

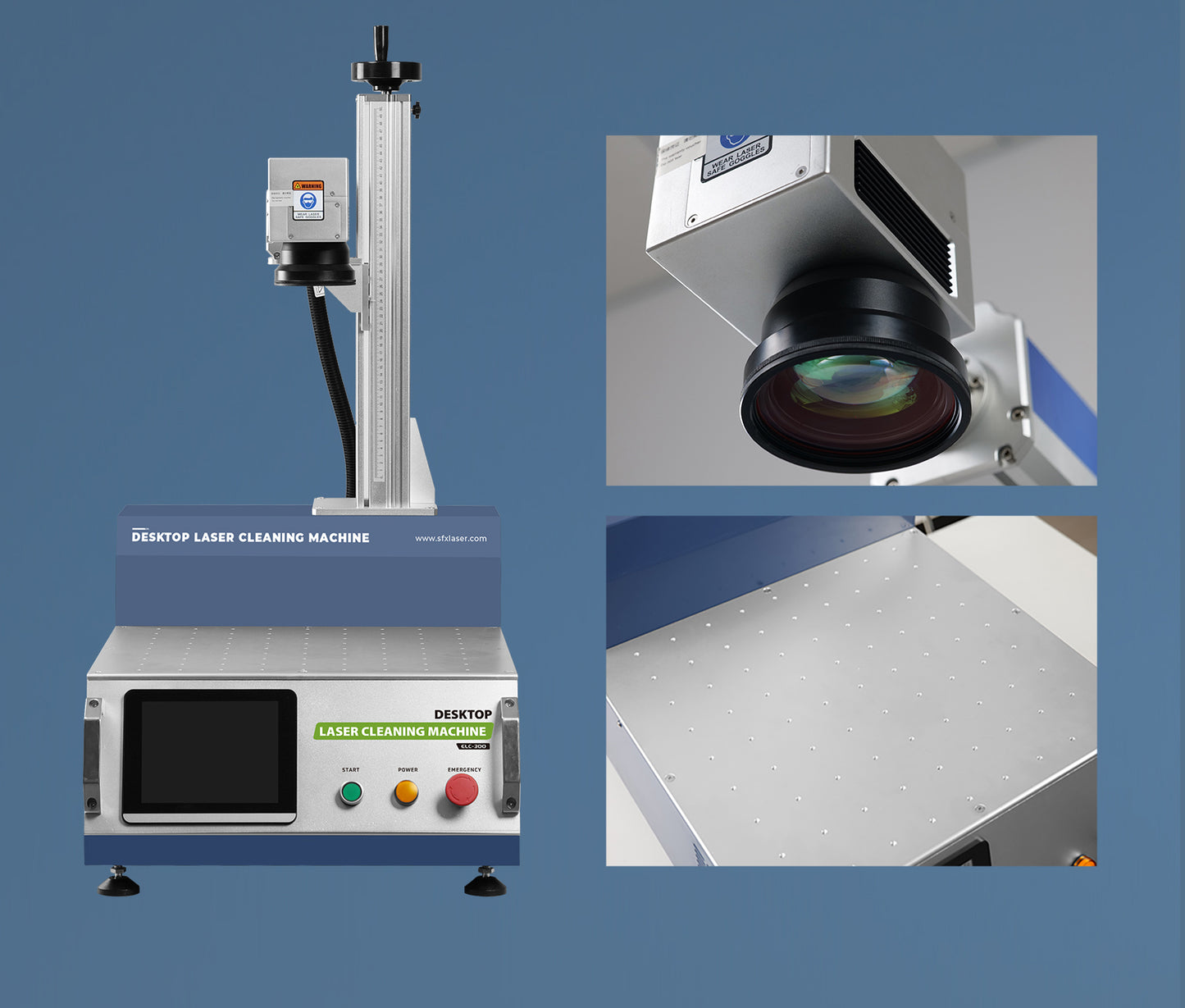

🚀Laser power:200W/300W, laser wavelength:1064nm, operating mode:Pulse, modulation frequency:1-3000kHz, adjustable height:450mm, scanning area:300*300mm(F420Lens), power configuration:AC220V±10%, 1.5kw/2kw, cooling method:air cooling.

🚀Desktop laser cleaning machine reduces repetitive manual work and improves efficiency. The desktop design is suitable for fine cleaning of workpieces and batch cleaning/welding of small workpieces. This machine is primarily a cleaning machine, with welding as a secondary function. Allowable welding conditions: <1mm stainless steel plate, aluminium plate and other metal materials welding.

🚀Applicable area: aviation, rubber mould, electronic machinery, equipment manufacturing, auto parts, food processing; Applied materials: resin, greasy dirt, rust, coating, plating, paint it can meet the processing of a variety of modeling workpieces and achieve efficient cleaning.

🚀Lift to adjust the focus, adjustable height:450mm, it supports cleaning for objects of different heights. Touch operation screen, simple and easy to use.

🚀Both continuous laser cleaner and pulsed laser cleaner can remove rust or paint on the surface of materials to achieve the effect of cleaning, under the same power conditions, the cleaning efficiency of pulsed laser cleaner is much higher than that of continuous laser cleaner. With high precision, it is necessary to strictly control the heating of the substrate, and the application scenarios that require the substrate to be non-destructive, such as molds, should choose a pulsed fiber laser cleaner.

Email: lyxctech@gmail.com

oscar@sfxlaser.com

Whatsapp: +86 13592083781

You can also leave us your comment for your interested items. We will respond within 24 hours! Thanks!

LYXCTECH Pulsed Laser Cleaning Machine Desktop Design Laser Machine for Cleaning and Welding 200W/300W

-Suitable for fine cleaning of workpieces and bulk cleaning/welding of small parts

👍Features Of Laser Cleaning Machine

- Lift to adjust the focus, supports cleaning for objects of different heights.

- Integrated air-cooled structure, no need to add water, save the trouble of regular water change.

- Touch operation screen, simple and easy to use

☀️Optional accessories

- With a rotating axis: 360° cleaning

- With a conveyor belt: extended assembly line cleaning

💕Product Parameters

- Model: ELC-200/300

- Laser power: 200W/300W

- Laser wavelength: 1064nm

- Operating mode: Pulse/modulation

- Modulation frequency: 1-3000kHz

- Adjustable height: 450mm

- Scanning area: 300*300mm(F420Lens)

- Power configuration: AC220V±10%, 1.5kw/2kw

- Cooling method: air cooling

- External dimension: 785*520*1020mm

- Net weight: 66.5kg 69.5kg

🎗️Applicable Area

- Aviation, rubber mould, electronic machinery, equipment manufacturing, auto parts, food processing

🚩CW VS Pulsed Laser Cleaner

- The dust could be removed both by MOPA pulsed fiber laser and CW fiber laser. Under same average output power, the cleaning efficiency of MOPA pulsed fiber laser is far more quicker than the efficiency of CW fiber lasers. In the meantime, precise heat control between cleaning and melting promise the good cleaning performance, without hurting the substrate.

- However, the cost for CW fiber laser is lower, which compensates the disadvantage of the cleaning efficiency by increasing the average output power. But it will bring in worse heat effect, which will hurt the substrate.

- Thus different cleaning application will request different laser model.For precise cleaning, such as mold cleaning, it’ll be better to choose MOPA pulsed fiber laser. For some large steel structures, pipes, etc., due to the large volume, fast heat dissipation and low requirement for substrate damage, continuous laser will be a good choice.

✈️Shipping Policy

- All of our laser machines would be shipped by express like DHL/UPS/FedEx/TNT.

- All prices are including shipping to your door.

- Order processing time: 2 to 3 business days.

- Delivery time: 7 to 15 days.

❣️Warranty Policy

- 1. The warranty period of this product is one year for the whole machine, and the warranty period for the laser source is two years.

- 1.1 From the date of purchasing this product, our company provides free warranty within one year. If the machine need to be returned to the factory for repair, the user only needs to bear the cost of two-way transportation.

- 1.2 This product is repaired free of charge for life, and the user only needs to bear the cost of spare parts and two-way transportation.

- 2. The following scopes are not covered by warranty:

- 2.1 Damage caused by improper use such as violent bumping, bending, etc.

- 2.2 Human-caused damage

- 2.3 Laser accessories and consumables are not guaranteed (galvanometers, field mirrors and other optical parts, Integrated cables, etc. are not covered by the warranty).